- Products

- /

- Mark IV Tank Floor Scanner

Mark IV Tank Floor Scanner

Concerned about hidden corrosion in your storage tanks?

Undetected tank floor corrosion can lead to costly failures—but the Mark IV Tank Floor Scanner helps you stay ahead of potential issues. Designed by MFE Enterprises, this industry-leading inspection tool uses advanced magnetic flux leakage (MFL) technology to quickly and accurately detect corrosion and defects, ensuring the integrity of your storage tanks.

Built for non-destructive testing (NDT) professionals, the Mark IV combines precision, efficiency, and ease of use, making it the go-to solution for thorough tank floor evaluations.

Its robust construction and advanced features empower inspection teams to detect problems early, prevent failures, and ensure compliance—saving time and money in the long run.

Don’t let unseen damage put your operations at risk. Upgrade your inspections with the Mark IV and protect your assets with confidence.

BENEFITS OF THE MARK IV

The Mark IV Tank Floor Scanner offers several key benefits for technicians and asset owners alike, including:

Cost-Effective Maintenance

By detecting corrosion and defects early, the Mark IV helps prevent major failures that could result in costly repairs or tank replacements. Early detection also reduces the risk of environmental damage and contamination, further protecting business assets and operations.

Improved Safety

Identifying defects in tank floors is critical for maintaining safe operations. The Mark IV enables businesses to proactively address issues that could lead to leaks or catastrophic tank failure, ensuring that storage tanks meet safety standards.

Time-Saving Efficiency

With its fast scanning capabilities and real-time data output, the Mark IV reduces the amount of time required for inspections, minimizing downtime and disruption to business operations. This speed and efficiency are vital in industries where uninterrupted production is crucial.

Compliance with Industry Standards

The Mark IV Tank Floor Scanner helps ensure that businesses remain compliant with industry regulations for tank integrity, safeguarding against fines and operational shutdowns.

BUY OR RENT

Request a Quote

What Is the Mark IV Tank Floor Scanner?

The Mark IV Tank Floor Scanner is a high-performance device specifically developed to detect corrosion and metal loss in storage tank floors. It operates using MFL technology, which is highly effective at identifying flaws that can compromise the integrity of tanks used in industries such as oil and gas, chemicals, and storage.

By passing over the surface of the tank floor, the scanner detects irregularities in the magnetic field, highlighting areas where corrosion or metal loss has occurred. This allows for timely maintenance and repairs, preventing leaks, contamination, and costly damage.

KEY FEATURES OF THE MARK IV

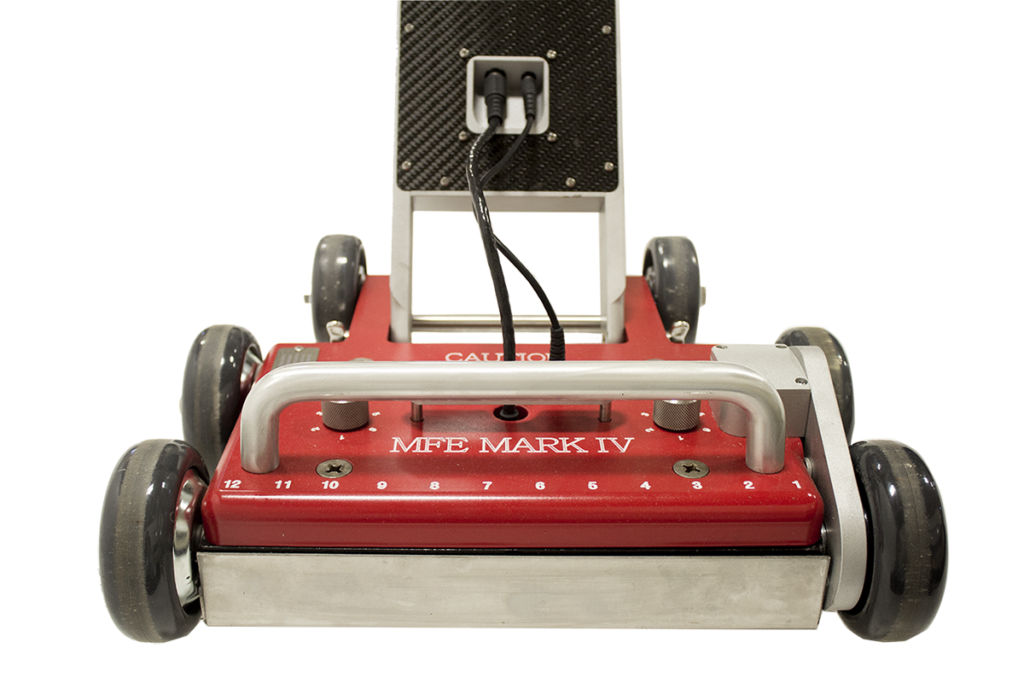

The Mark IV is designed for accuracy, durability, and efficiency, making it an invaluable tool for NDT professionals. Some of its standout features include:

Advanced Magnetic Flux Leakage (MFL) Technology

The Mark IV uses Magnetic Flux Leakage (MFL), a proven method for detecting corrosion and defects in ferrous materials. This technology enables the scanner to identify hidden flaws below the surface of the tank floor for a comprehensive assessment of its condition. It can scan through up to 1/2 inch of combined steel and coating thickness, with an optional High Flux Bridge Upgrade extending performance to approximately 0.75 inches.

Lightweight Design

At just 65 lbs, the Mark IV is designed for ease of maneuverability without compromising on performance. Its lightweight build allows technicians to navigate the scanner over tank floors more easily, reducing fatigue and enhancing productivity.

Increased Efficiency and Speed

With the Mark IV, inspections can be completed faster than ever. The scanner’s design and intuitive controls make it easy to operate, allowing technicians to cover large areas quickly while maintaining accuracy.

Real-Time Data Collection

The scanner provides real-time data, allowing operators to immediately view results and assess the condition of the tank floor during the inspection process. This feature enables prompt decision-making and reduces downtime between inspections and repairs.

Enhanced Accuracy

The Mark IV Tank Floor Scanner is engineered to deliver high-resolution data, ensuring that even small defects and areas of corrosion are detected. This level of precision helps technicians make informed decisions about necessary repairs and maintenance.

Versatility

The Mark IV is suitable for use across a variety of industries, from oil and gas to chemical and food processing. Its versatility makes it an essential tool for any business relying on the integrity of storage tanks to safeguard operations.

Why Choose the Mark IV Tank Floor Scanner?

The Mark IV Tank Floor Scanner from MFE Enterprises is a powerful, reliable solution for detecting corrosion and defects in storage tank floors. Its advanced MFL technology, real-time data collection, and user-friendly design make it a top choice for NDT professionals across various industries.

Combined with MFE Enterprises’ dedicated support services, including certified training, repairs, and calibrations, the Mark IV ensures that your inspections are completed with the highest levels of accuracy and efficiency.

Whether you’re protecting critical infrastructure in the oil and gas sector or ensuring compliance in food processing, the Mark IV Tank Floor Scanner delivers the performance and peace of mind you need to keep operations running smoothly.

MFE Edge: A Complementary Tool to the MFE Mark IV

The MFE Edge is the perfect complementary scanner to the Mark IV Tank Floor Scanner, enhancing inspection capabilities with its lightweight, portable design.

While the Mark IV excels at efficiently scanning large tank floors with high-speed magnetic flux leakage technology, the MFE Edge is designed to access hard-to-reach areas, such as tank shell edges and tight spaces where larger scanners cannot operate.

Together, these two advanced tools provide a comprehensive solution for tank floor inspections, ensuring full coverage, improved accuracy, and enhanced safety.

By combining the Mark IV’s high-speed, broad-area scanning with the MFE Edge’s precision in confined spaces, inspectors can achieve the most thorough and reliable results possible.

Recent Upgrades

Built on feedback from the field and a commitment to continuous innovation, the latest enhancements to the MFE Mark IV are designed to increase ruggedness, improve operational reliability, and reduce maintenance needs. These refinements further strengthen the performance and user experience you’ve come to expect.

Tougher Aluminum Handles for Demanding Environments

The new aluminum handles bring enhanced durability to the MFE Mark IV, delivering a sturdier, longer-lasting grip that stands up to daily wear in the harshest inspection conditions.

Lightweight Design

Improved foldable handles offer increased structural resilience, making the unit easier to transport and maneuver while holding up to heavy use in the field.

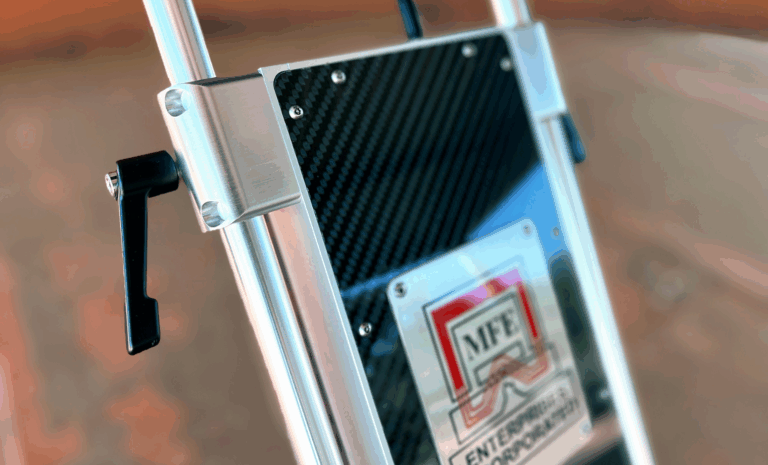

Stronger Dual Cam Levers for a Rock-Solid Lock

Upgraded dual cam levers provide a tighter, more dependable lock on the handle assembly, ensuring stability and confidence during every scan.

Permanently Attached Signal Cable for Greater Reliability

The updated signal cable design eliminates a common point of failure by keeping the connection securely fastened to the sensor bar—minimizing downtime and keeping inspections on track.

MFE Enterprises: Certified MFL Training and In-House Support

MFE Enterprises is dedicated to providing comprehensive support to users of the Mark IV Tank Floor Scanner. We offer a certified Magnetic Flux Leakage (MFL) training course, designed to equip technicians with the skills needed to operate MFL technology effectively.

This hands-on training ensures that inspection teams can maximize the performance and accuracy of the Mark IV, as well as other MFL-based tools.

In addition to training, MFE Enterprises also provides in-house repairs, calibrations, and ongoing support for the Mark IV and other inspection equipment. Our commitment to customer satisfaction means that your equipment will always be in top condition, with fast turnaround times for repairs and regular calibrations to ensure peak performance.

The MFE Edge Tank Floor Scanner

For businesses that require a smaller, more lightweight scanner, MFE Enterprises also offers the MFE Edge Tank Floor Scanner. Weighing just 61 lbs, the MFE Edge delivers the same high-level MFL performance as the Mark IV, but with enhanced portability for hard-to-reach areas.

Like the Mark IV, the MFE Edge is designed for efficiency and accuracy, making it an ideal complement for comprehensive tank inspections.

Download your brochure

Use the button below to download your free brochure to read more about the MFE Mark IV Tank Floor Scanner.