- Products

- /

- MFE PipeScan

MFE PipeScan

The MFE PipeScan is a high-speed, field-ready magnetic flux leakage (MFL) inspection tool that streamlines pipeline assessments by delivering accurate, real-time results, without the hassle of coating removal or extensive prep. The PipeScan quickly identifies corrosion and other subsurface defects without interrupting operations.

It’s built for demanding industrial environments to help inspection teams work faster, combining real-time digital feedback with customizable alarms, ensuring inspectors are alerted only when it matters.

It scans through protective coatings, adjusts to a wide range of pipe sizes, and minimizes prep time—empowering teams to reduce downtime, enhance safety, and make confident, data-driven maintenance decisions.

BENEFITS OF THE MFE PIPESCAN

The MFE PipeScan offers key benefits for asset owners and technicians alike, including:

Inspection Efficiency and Speed

The MFE PipeScan is engineered for fast, uninterrupted inspections scanning up to 3 feet per second and covering wide areas in a single pass. Its modular design supports up to six MFL bridges, allowing operators to detect defects quickly while reducing downtime and boosting productivity in the field.

Accurate Detection and Real-Time Data

Get clear, reliable results with real-time digital volume loss signals and an adjustable threshold alarm system. The PipeScan only alerts when an actual defect is detected, helping inspection teams focus on what matters. Its Freeze Screen Alarm and built-in data visualization features ensure nothing gets missed.

Versatility and Coating Compatibility

The PipeScan can scan through non-magnetic coatings up to 12 millimeters thick, eliminating the need to strip protective layers. It works with pipes 5 inches in diameter and larger. Its rugged, user-friendly design makes it well suited for diverse field conditions.

Cost Savings and Smarter Reporting

Faster inspections and accurate targeting reduce the need for unnecessary repairs and help lower operational costs. When paired with Scan Studio software, inspection data can be integrated into technical drawings, exported to PDF, and combined with other NDT results for a complete view of pipeline integrity.

BUY OR RENT

Request a Quote

What is the MFE PipeScan?

The MFE PipeScan is a high-speed MFL scanner designed to detect signs of volumetric wall loss in pipelines. It identifies areas where corrosion or material loss has occurred, allowing inspection teams to quickly flag and document potential problem spots without removing coatings or disrupting operations.

Rather than quantifying defects, the PipeScan highlights where attention is needed, helping teams focus resources on the most critical areas. Its rugged design and flexible configuration support a wide range of pipe sizes and coatings, making it ideal for fast, effective screenings in demanding environments.

Paired with MFE’s reporting software, the PipeScan gives operators the insight needed to prioritize maintenance, plan follow-up testing, and reduce the risk of unexpected failures.

KEY FEATURES OF THE MFE PIPESCAN

The MFE PipeScan combines advanced MFL technology with practical field-ready design to deliver fast, accurate, and efficient pipeline inspections. From its powerful sensor system to real-time digital feedback and reporting capabilities, here are the key features that set the PipeScan apart:

Advanced MFL Technology

At the core of the PipeScan is a high-saturation magnetic bridge powered by rare earth magnets and a precision sensor array. This setup enables accurate detection of volumetric wall loss by identifying magnetic flux leakage as the scanner moves along the pipe.

High-Speed, Wide-Area Scanning

The PipeScan performs inspections at speeds up to 3 feet per second. It supports configurations of 3 to 6 MFL bridges, allowing coverage from 8.25 to 16.5 inches in a single pass, ideal for efficiently scanning large surface areas without sacrificing accuracy.

Versatile Pipe and Coating Compatibility

Fully adjustable for pipes starting at 5 inches in diameter, the PipeScan can scan through non-magnetic coatings up to 12 millimeters thick. This eliminates the need to remove protective coatings and reduces prep time in the field.

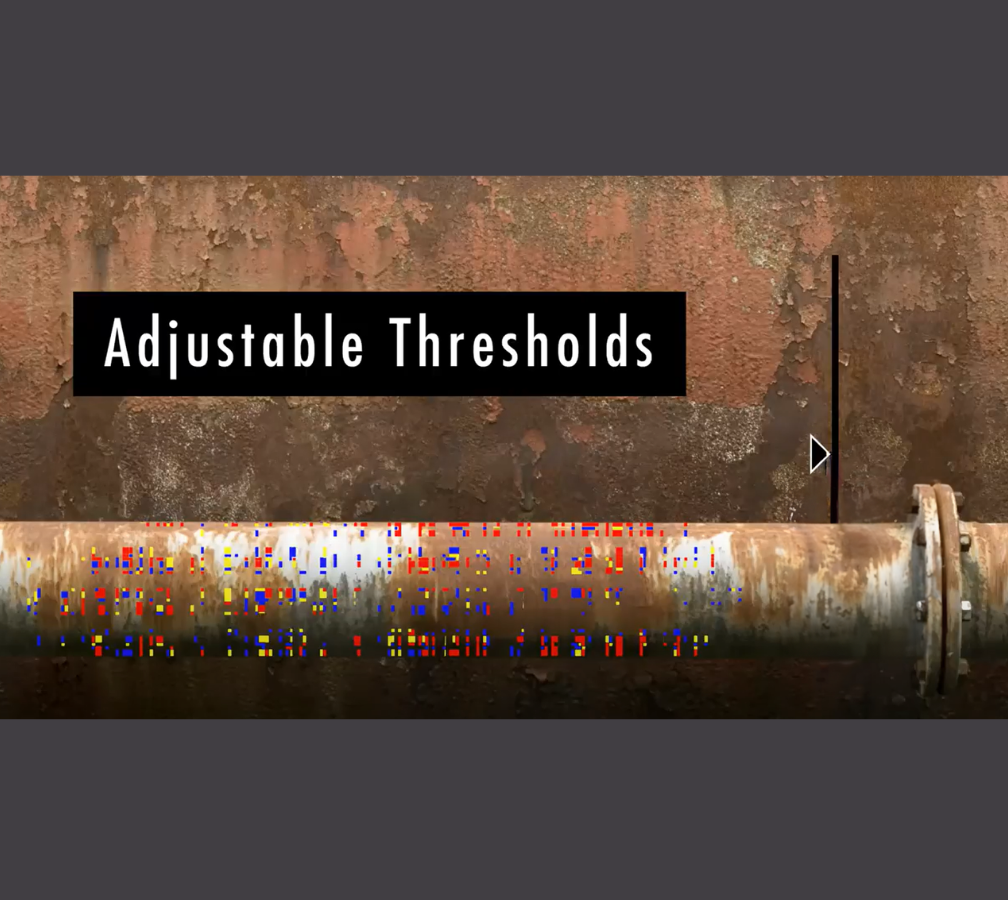

Real-Time Feedback and Alarm System

Operators receive live feedback via a digital display, which shows volume loss signals in real time. A fully adjustable threshold/alarm system alerts users only when potential defects are detected, and a Freeze Screen Alarm feature helps capture and review key findings.

Integrated Touchscreen and Rugged Design

The included Panasonic ToughBook tablet allows for on-the-go adjustments to gain and alarm settings. With a total weight of around 35 lbs (plus 5.25 lbs per MFL bridge), the PipeScan is built to withstand tough industrial environments while remaining portable and user-friendly.

Seamless Reporting and Software Integration

Compatible with Scan Studio software, the PipeScan allows inspection data to be uploaded, visualized, and integrated into technical drawings. Users can add supporting data from other NDT methods and export reports to PDF for fast, clear documentation of pipeline conditions.

Why Choose the MFE PipeScan?

With over 30 years in the field, MFE Enterprises is a trusted name in MFLe inspection technology. The MFE PipeScan reflects that legacy, offering inspection teams a dependable, field-proven solution for identifying volumetric wall loss with speed and confidence.

Designed for real-world conditions and backed by MFE’s global support, the PipeScan helps streamline inspection workflows and support critical maintenance decisions. Its results are easily documented for professional reporting, giving teams the information they need to keep operations safe, efficient, and compliant.

Support You Can Count On from MFE Enterprises

MFE Enterprises has built a strong reputation not just for reliable inspection tools, but also for the support that backs them. When you purchase the MFE PipeScan, you’re partnering with a company known for standing behind its equipment and helping teams stay ready for the field.

Reliable Performance, Long-Term Value

The PipeScan is built for tough environments and long-term use. Its rugged construction is designed to hold up under demanding inspection conditions, helping reduce downtime and minimize maintenance needs.

Repair and Technical Assistance

If issues arise, MFE’s service team is available to provide repairs and technical guidance. Whether it’s replacing components or answering product questions, you’ll have access to knowledgeable support when you need it.

Download your brochure

Use the button below to download your free brochure to read more about the MFE PipeScan.